For Well being, Security, and Atmosphere (HSE) managers in complicated industrial operations, the function comes with a continuing psychological guidelines and give attention to incident prevention. The implications of lacking one thing will be extreme.

Widespread issues that hold HSE managers up at night time embrace:

- “Will right now be the day a preventable accident occurs?”

- “Are our incident prevention and security controls working, or simply assumed to be?”

- “Do we’ve got the information to show compliance if regulators ask tomorrow?”

- “Can I spot hazards earlier than my staff will get harm, slightly than after the occasion?”

- “What am I not seeing proper now that would trigger a shutdown?”

These aren’t summary worries: they’re rooted in laborious information.

Globally, over 2.78 million employees die every year from work-related accidents or illnesses (ILO), and 374 million undergo non-fatal accidents.

Within the US alone, office accidents value $167 billion yearly (NSC), with oblique prices – from misplaced productiveness to broken status – additional multiplying the affect.

Why incident prevention is the precedence

Amongst all security measures, incident prevention and threat mitigation stand on the high as a result of they:

- Immediately forestall accidents and fatalities earlier than they happen

- Keep away from expensive shutdowns and operational disruption

- Ship speedy ROI by means of diminished claims, fines, and downtime

The stakes are excessive: the common value of a office harm declare is $41,757 (NSC), whereas a fatality can exceed $1.4 million in direct prices.

That is with out even counting reputational prices and operational injury. In high-risk industries, a single severe accident can jeopardize contracts, investor confidence, and even licensing.

4 functions of AI Imaginative and prescient for incident prevention

1. Forklift and automobile motion monitoring

Key statistics:

Industrial autos trigger over 11% of office fatalities and 1000’s of accidents yearly. And forklift accidents alone trigger 85 fatalities and 34,900 severe accidents yearly (OSHA).

Key HSE issues:

- Are drivers working inside protected pace limits?

- Are pedestrians staying out of auto zones?

- How can we handle blind spots in busy areas?

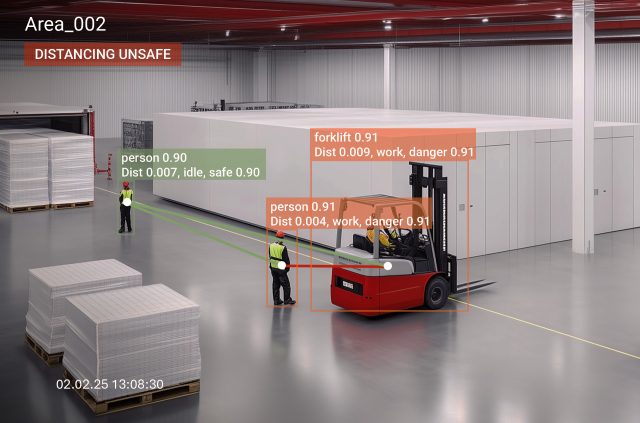

AI Imaginative and prescient permits:

- Computerized pace and route compliance checks

- Actual-time alerts when pedestrians enter hazard zones

- Blind-spot and intersection monitoring to forestall collisions

2. Slip, journey, and fall detection

Falls are the main trigger of misplaced workdays and one of many high three causes of office fatalities. Slips, journeys, and falls end in over 244,000 severe office accidents yearly within the US.

Key HSE issues:

- Can we detect hazards earlier than somebody will get harm?

- How briskly can we reply if a fall occurs?

- Are we monitoring recurring threat areas?

AI Imaginative and prescient affords:

- Automated hazard recognizing for spills, muddle, or uneven surfaces

- On the spot alerts when a fall happens for fast medical response

- Heatmaps of hazard places for focused upkeep

3. Machine guarding compliance

Unguarded equipment is a direct path to catastrophic accidents. OSHA estimates $2 billion in annual prices from amputations and crush accidents linked to unguarded equipment.

Key HSE issues:

- Are all security guards and interlocks in place earlier than operation?

- How can we catch unsafe bypasses in actual time?

- Can we show compliance throughout an audit?

AI Imaginative and prescient can:

- Confirm guards are in place earlier than the equipment begins

- Detect guide overrides or eliminated obstacles

- Create a visible audit path for regulatory proof

4. Close to-miss detection

Close to misses are sometimes ignored, but they’re main indicators of great future incidents. Research present for each severe harm, there are 29 minor accidents and 300 close to misses (Heinrich’s Security Pyramid).

Key HSE issues:

- What number of hazards are we lacking just because no harm occurred?

- Can we use near-miss information to revamp processes?

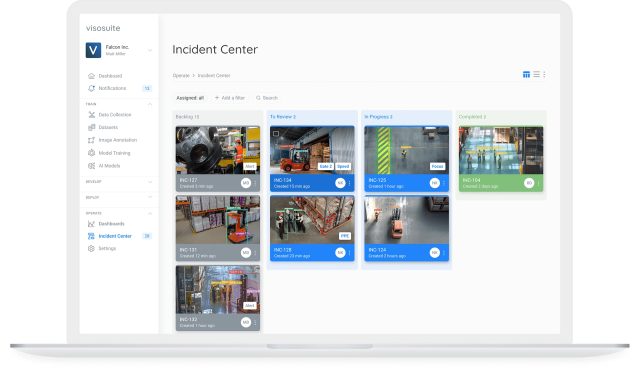

With AI-powered cameras:

- Unsafe proximity and interactions are robotically flagged

- Incident movies are logged for assessment and root trigger evaluation

- Patterns emerge for preventive motion earlier than actual hurt happens

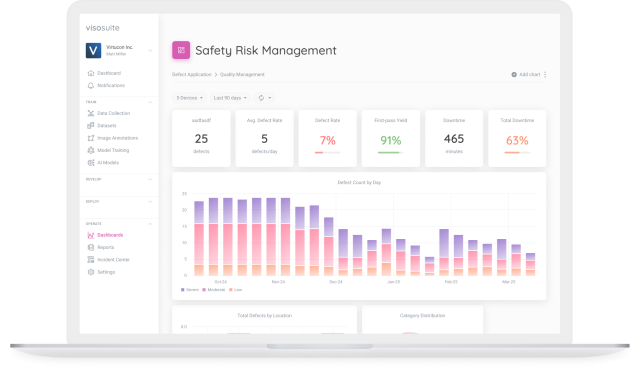

The ROI of incident prevention

Incident prevention isn’t nearly security – it’s about operational resilience.

Think about, for instance, that:

- A single prevented forklift accident can save $188,000 in direct and oblique prices

- Lowering fall incidents by 25% can reduce harm claims by tens of 1000’s per yr

- Bettering guarding compliance reduces downtime from machine lockouts or investigations

Shaping a safer, smarter future

For industrial HSE leaders, incident prevention is probably the most pressing and cost-effective security funding obtainable.

By deploying laptop imaginative and prescient in these 4 key areas, managers can transfer from reactive to predictive security: making a office the place hazards are addressed earlier than hurt happens.

The payoff is measured not simply in lives protected, however in uninterrupted productiveness, regulatory confidence, and belief from each employees and stakeholders