Ergonomic damage is a silent killer of producing productiveness.

Your greatest line supervisor calls in sick with again ache. Once more.

Two extra employees from the identical shift are on restricted obligation for wrist accidents.

You’re scrambling to cowl shifts whereas managing employees’ compensation claims that may price your organization a median of $50,000 per incident.

Welcome to manufacturing’s costliest hidden downside: ergonomic damage and musculo-skeletal problems (MSDs).

By the numbers: manufacturing’s ergonomic damage disaster

MSDs price US producers over $13 billion yearly – greater than the GDP of many small nations. In contrast to machine failures that set off rapid alerts, ergonomic accidents develop invisibly, one repetitive movement at a time.

The statistics are staggering.

The human and monetary price:

- Manufacturing has an MSD incident price of 41 per 10,000 employees – practically double the personal sector common

- 502,380 days away from work as a consequence of MSDs in 2021-22 alone

- Common employees’ compensation declare for an MSD: $50,000+

- Employee accidents price employers greater than $2,000 per worker yearly

- Hidden prices (time beyond regulation, retraining, productiveness loss): 4-5x the direct medical prices

The operational actuality:

- 38% of all office accidents in manufacturing are MSDs

- Common time to return to work: 31 days for extreme instances

- Repeat damage price: 25-40% increased for employees with earlier MSDs

These aren’t simply statistics – they characterize actual bottom-line affect in your operations.

The normal method to ergonomic damage: too little, too late

Most manufacturing amenities depend on reactive ergonomic administration: annual assessments that miss day-to-day variations, incident reporting after accidents happen, and periodic security walks overlaying lower than 5% of precise work carried out.

This method is like monitoring machine well being by ready for catastrophic failure.

By the point you see the issue, the harm is completed.

Laptop Imaginative and prescient: the ergonomic revolution

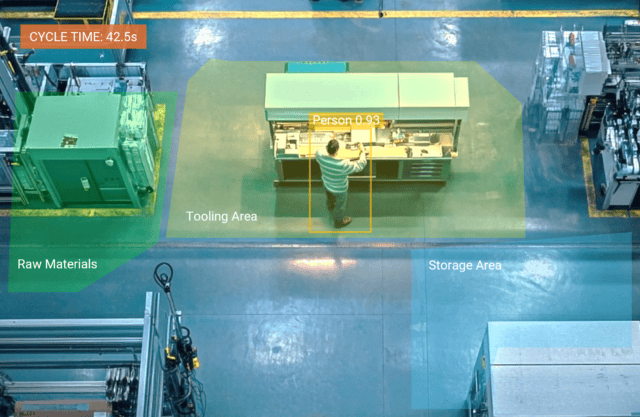

AI-powered laptop imaginative and prescient transforms ergonomic monitoring from re-active to pro-active, offering steady oversight that human observers can’t match.

Trendy programs analyze dwell video feeds from current cameras, utilizing skilled fashions to detect:

- Posture evaluation: awkward bending, reaching, and twisting

- Repetitive movement patterns: high-frequency, high-risk actions

- Load dealing with: improper lifting strategies

- Extended static positions: prolonged intervals in dangerous postures

What makes AI Imaginative and prescient totally different:

- 100% protection: each employee, each shift, every single day

- Actual-time alerts: rapid intervention earlier than damage happens

- Quantifiable knowledge: metrics that show ROI and information funding choices

Actual-world affect: the enterprise case in motion

Case examine: automotive elements producer

A 500-employee automotive provider carried out laptop imaginative and prescient ergonomic monitoring throughout three manufacturing traces.

Earlier than implementation:

- 23 MSD incidents requiring medical remedy

- $1.2 million in employees’ compensation prices

- 15% turnover price attributed to damage considerations

After implementation:

- 6 MSD incidents (74% discount)

- $310,000 in employees’ compensation prices (74% discount)

- 8% turnover price (47% discount)

- 22% enchancment in line effectivity

- ROI achieved in 14 months

The main indicators that change all the things

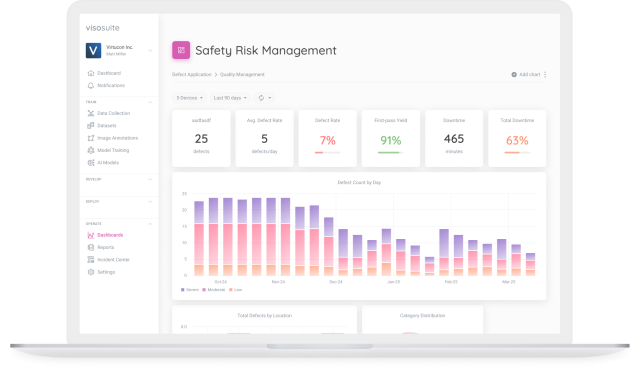

Laptop imaginative and prescient supplies metrics that drive steady enchancment:

- Actual-time ergonomic damage KPIs:

- Danger publicity time per employee/shift

- Repetitive pressure frequency and depth

- Intervention success charges

- Workstation comparative threat scores

This knowledge transforms security managers from compliance officers into strategic companions, offering executives with actionable intelligence that drives each security and productiveness enhancements.

Addressing the manager questions

“How do we all know this gained’t disrupt manufacturing?”

Laptop imaginative and prescient integrates with current digital camera programs and requires zero adjustments to employee procedures. Implementation takes 48-72 hours per line with no manufacturing downtime.

“What about employee privateness and acceptance?”

Trendy programs give attention to posture and motion patterns, not particular person identification. Staff usually report feeling “taken care of” fairly than “watched.”

“Can we show ROI earlier than full deployment?”

Step one is beginning with a pilot program on the highest-risk line. Inside 90 days, there may be quantifiable knowledge on incident discount, productiveness enhancements, and price financial savings.

The hidden productiveness multiplier

Past damage prevention, AI Imaginative and prescient delivers sudden advantages:

- High quality enhancements: stopping ergonomic pressure reduces high quality defects by 15-25% throughout high-demand intervals.

- Effectivity features: correct ergonomics reduces employee fatigue, growing sustained efficiency with common productiveness enhancements of 12-18%.

- Retention advantages: firms with proactive ergonomic applications report 40% higher retention charges, saving $15,000+ per prevented turnover.

- Insurance coverage benefits: carriers provide premium reductions as much as 35% for amenities with demonstrated proactive security applications.

The aggressive crucial

When you’re studying this, opponents might already be implementing laptop imaginative and prescient ergonomic monitoring.

Early adopters of AI Imaginative and prescient acquire benefits via:

- Decrease working prices from lowered damage bills

- Increased productiveness from much less fatigued workforces

- Higher expertise attraction as safety-conscious employees desire proactive employers

- Improved provider relationships as prospects require security efficiency metrics

The $13 billion downside, solved

Manufacturing’s $13 billion ergonomic downside has an answer. Laptop imaginative and prescient know-how is confirmed, scalable, and delivering measurable outcomes throughout the trade.

Day by day you wait, preventable accidents happen in your facility.

Every month you delay, opponents acquire benefits via pro-active security applications.

Each quarter you postpone implementation, you’re leaving cash on the desk whereas placing employees in danger.

Laptop imaginative and prescient ergonomic monitoring represents the way forward for manufacturing security – the place prevention replaces response, the place knowledge drives choices, and the place each employee goes dwelling wholesome.

The know-how is obtainable now, and the ROI is confirmed.

The one query is: will you lead the change or observe others who’ve already begun